Manufacturer Management Consulting

This business process management case study is about a manufacturer providing custom metal fabrication and parts assembly located in Indianapolis, IN. Their fabricated solution offerings include laser cutting, forming, stamping, material finishing, welding, engineering, assembly, coatings, and in-house mill and lathe capabilities. Operating since 2007, our client is a family-operated business that offers holistic solutions to project needs rather than having to rely on multiple manufacturing shops to process one part, essentially a one-stop-shop.

Business Status and Initial Challenges

The client is a very personable individual and good at selling but, typical of many owners, not good at managing the business. The daughter manages the office and shipping and while capable has no prior experience in her position. The Production Manager has risen through the ranks starting out as a Fabricator and taking over as Production Manager, replacing his father when he retired but having no other experience in managing anything much less a machine shop.

The business was flat at $2m to $2.5m annually over five-plus years. The client could sell more but Operations would not be able to fulfill those orders. They were faced with a significant backlog and fearful of taking on new business because of not meeting deadlines. The client had a software system that listed all open orders but wasn’t able to project timelines when different stages of when work might be done. For example, a part might need to be cut, then formed before grinding and welding but they were only able to manually move parts from one stage to the next. The only answer was to “plow” through the backlog with a singularity of pursuit and to require extensive (and expensive) over time. They tried “farming” some of the work out to third parties but because the jobs were usually one-off, as opposed to production type runs, the sub-contractors were either not willing to do the work or would price the job at a rate that was exorbitantly high.

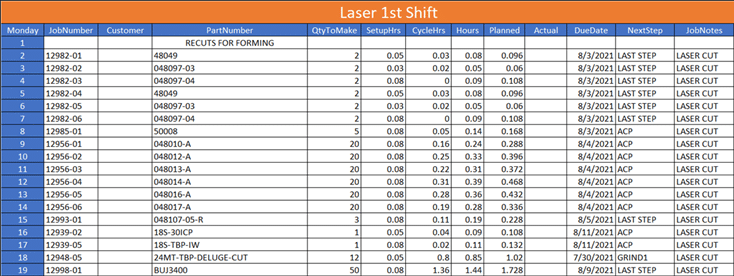

A Daily Huddle had been installed but the Production Manager remarked that while his Operators liked the meeting, he did not find it useful. The Operators were a young and amiable group but not a lot of experience. The Production Manager would hand off a list of jobs to be worked from their ERP system that ranged over two months. The result is that the Operators would pick and chose what they wanted to work on. The only prioritization done was due to the Production Manager expediting orders that were behind. This prioritization resulted in interrupting work in the process further slowing down operations and continuing to contribute to the backlog.

Another backlog contributor was due to the Operators of the Lazar equipment leaving the table with parts that had been finished and could have been moved to the next stage of fabrication. There were two machines and while the second Lazar was not able to process all parts, there was no sense of urgency to have these machines up and running all the time. This was a very simple operation in that the machine could be loaded and left alone while it was cutting the sheet metal, then pull the sheet out and insert a new sheet to be cut. Instead, the Operators were quite often “wandering” and letting the machine sit idle or not taking advantage of the second Lazar where both could be run at the same time.

To compound the backlog issues, especially as related to the Lazar machines, they required programming which was often not being done until the sheet metal was ready to be cut and the machine would wait until the Production Manager could find the time to do the programming. This could mean hours the machine would sit idle waiting for programming.

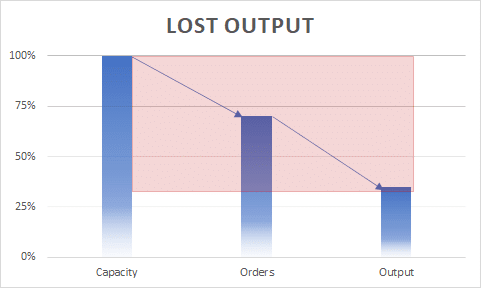

To summarize, there were a “comedy of errors” that were contributing to the high levels of backlog. Overall, the Business Process Management (BPM) or Management Operating System (MOS) was incomplete with any elements that did exist were not being effectively used. Examples of the weakness of their business process management included poor planning, relying on software they did not know how to use, inadequate distribution of work, lack of discipline in equipment management, and failure to keep the processes flowing. They wanted to do the work but just did not know how to manage the work processes. Put another way, of the 100% capacity they had operationally, they only had sales to utilize 70% of that capacity but due to inefficiencies they were only able to produce 50% of those sales as shown in the schematic.

Business Process Management Solutions

Scheduling –

Given that they did not know how to use their ERP software, I built a spreadsheet from the listed jobs. Those jobs had standards, of questionable accuracy, but were good enough to work with and I backed off that standard by 20% to allow for buffer. I then took the list of work and broke out those jobs that were due the soonest by workstation and filled up an eight-hour day over two shifts where it applied to the Lazar equipment. I did this by week until all the jobs were consumed, about four weeks.

Unfortunately, because the ERP output was so inaccurate it was not capturing all the backlog and was including the jobs that had already shipped with no one knowing how to clean out the system. We ultimately learned that further training would cost thousands of dollars and, eventually, the provider admitted that the system did not have the functionality required. Instead, the Production Manager would do a weekly “cleansing” of the list, create a four-five week lookahead, produce a weekly plan by day by station took around two hours which is reasonable in that this is a core activity for a Production Manager.

Daily Huddle –

I then had the Production Manager, in the Daily Huddle, release the parts to each operator based on a day’s worth of work, only, listed in the order in which the work was to be completed. This eliminated the picking and choosing of work that the operators had done in the past.

The Production Manager posted this above his desk and used it as a daily guide. As a consequence, we agreed that Programming would be adhered to during the allocated times and that we would stay three days ahead so that the Lazar machines would never be down due to programming not being done.

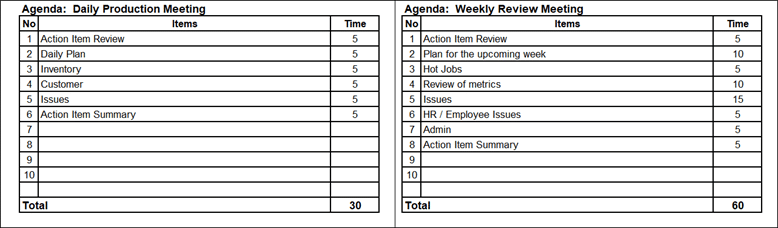

Daily Production (DPM) and Weekly Review (WRM) Meetings –

Both meetings were designed with a focus on planning and scheduling. During the DPM, the Production Manager met with the Office Shipping Manager, who also managed materials, and they discussed the daily plan, what needed to be shipped, and ensured that materials had been ordered and were arriving timely adjusting the daily schedule as needed. The WRM included the Office Shipping Manager, the Engineer, and the top client with a focus on reviewing the plan for next week and ensuring that it could be appropriately executed, and adjustments were made as needed. In addition, during the WRM they were able to address long-term solutions such as developing strategies to reduce/eliminate rework.

Follow-up audits of these meetings show that they continue to be not only held and effective, but vital tools in driving their business.

Manufacturer Management Consulting Summary

In the beginning there were no metrics. The client did not know how to obtain KPI‘s from their ERP system, which would probably not have been very meaningful considering that data in the system was of limited quality, and the client did not track metrics manually. With only a few weeks to work with, I chose to identify and implement the MOS tools that would allow them to improve their productivity.

With strict adherence to the new scheduling tool and business process management and management operating system elements that had been implemented, the backlog was eliminated and they were able to maintain that zero balance. They now look at open orders and are running at approximately $400k in open orders at any given time, which is their sweet spot, currently. They had been running at $2.5m to $2.0m annually over the last five years or so but were now able to ramp up production by getting that backlog shipped out and were tracking to do $3.5m. The goal was to ship $58,000 per week and they were hitting weeks where they shipped $60,000 to $70,000 per week and were achieving highs that they had not done before. The most gratifying aspect of all of these improvements and results is that everyone agreed, from the Management Team to the Operators, that it didn’t “feel” that they had worked that hard.

Essentially, they were working smarter not harder. No longer were they trying to “bully” parts and jobs through the production process but driving the process through their BPM and MOS. In the last WRM I attended, I turned to the top client and told him he had to now go out and sell more to realize this excess capacity. The last time I checked they were on track to do $5m in this year!